Industrial interfaces

All vicosys® systems have industrial communication interfaces. They fulfil the highest standards of integration and flexibility.

- EtherCAT and PROFINET for real-time communication and end-to-end processes

- modbusTCP and TELNET for communication via Ethernet networks

- digital I/Os for maximum compatibility with older systems and stand-alone applications

Your system for thermography solutions

24/7 - Precise temperature measurement with Flir thermographic cameras and 'active thermography'

⇒ Technology page 'Thermography'

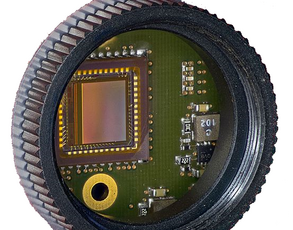

Your system for inspecting glass cylinders Type

Numerous images are required when inspecting small bubbles and inclusions in long glass cylinders. A small object field of 60 × 40 mm was selected for this application in order to reliably visualize objects as small as 0.1 mm. Due to the need to examine the glass cylinder in various angular positions, depth planes and linear inspection positions, over 100,000 individual images were taken. By using GenICam-compatible cameras with modern 10GigE technology, the inspection time in this application was reduced from 45 to just 8 minutes.

Your system for the inspection of folding rules

Five vicosys® 19001 systems with Intel® Core™ i9-10900K processors were used to fully inspect all 12 limbs of a 3-metre inch pole in just 0.5 seconds. Each limb is captured on both sides under two different lighting directions. This is followed by a print image check, surface check, butt cap check and dimensional check. The reliable detection of four-color print layers in the short inspection time was particularly challenging - a task that placed high demands on the computing power.

Worldwide Remote Support – Fast, Reliable, Unlimited

Vision & Control offers worldwide remote service that ensures fast, high-quality support. Our experts are always at your side for the diagnosis, maintenance, and optimization of your systems – no matter where your equipment is located. With secure remote access, we can perform maintenance, analyze errors, and implement improvements without the need for an on-site technician.

Benefit from minimal downtime, maximum efficiency, and a service that is truly accessible from anywhere.

vicosys® 6100 - Booksize

MV-Power on the top-hat rail

- At just 35 × 105 × 150 mm and a weight of 800 g

- Particularly compact PC-based multi-camera system

- Powerful Intel® processor

- EtherCAT and PROFINET cards can be integrated in the optional 2U expander

- Up to 16 cameras

Supports > 300 camera models including SWIR & thermography

vicosys®6300 - compact

Maximum speed for your switchboard:

- Maximum speed for your control cabinet:

- compact housing - image processing system as embedded PC

- powerful Intel® processor

- EtherCAT, PROFINET, dig. I/O and camera cards can be integrated

- Up to 16 cameras

Supports > 300 camera models including SWIR & thermography

⇒ To the product catalogue vicosys® multi camera systems

vicosys® 19001

High-end system for 19" racks with maximum speed:

- Flat design in 19" rack from 2 U

- Powerful processor (i7-10700E), 8 cores

- EtherCAT, PROFINET, dig. I/O and additional camera cards optional

- up to 16 cameras

supported > 300 camera models including SWIR & thermography

⇒ To the product catalogue vicosys® multi camera systems

It is a particularly user-friendly programming language based on dialog-guided commands that are executed step by step. The language also supports conditions, jumps, and complex logical operations.

Within vcwin, a wide range of image processing commands are available. These can first be tested using built-in test functions and then easily inserted into the program.

A great starting point is the beginner tutorials: Tutorials

The software itself is free of charge and can be tested in a simulator even without hardware: Downloads

For the overview the vcwin manual is also available here: Manual

Vision & Control offers also training on request.

HALCON scripts are created in the development environment (e.g. HDevelop), converted into executable formats and integrated via the vicosys® system control. Integration takes place via uploading in the system resources dialog and the corresponding HALCON call at the appropriate point in the test program. A HALCON runtime license on the vicosys® is required for this.

- Bundle Runtime License

For use on vicosys® for all functions (except DeepLearning) for HALCON.

- DeepLearning runtime license

For use on vicosys® for all functions (incl. DeepLearning) for HALCON.

- Developer license for HDevelop (MVTec)

This license is required per development workstation for HDevelop. HDevelop is an interactive development environment for the creation and testing of HALCON programs.

- Adapted runtime licenses on request

Reduced functional scopes are possible for specific use cases

Note: Runtime licenses are sold by Vision&Control with a dongle. Licenses are purchased via the order form (configurator) when purchasing a vicosys® image processing system. Licenses of the Progress type are always used. This allows the use of the latest HALCON library from the time of purchase + 2 years.

The performance is determined by the TOPS (Tera Operations per Second) and the number and type of processor cores used.

vicosys® systems offer high computing power for demanding image processing.

| CPU-Typ | Basic cycle | Turbo cycle | cores | Threads | RAM | TOPS | |

| vicosys® 6100 | Intel® Atom® x6413E | 1.5GHz | Bis zu 3 GHz | 4 | 4 | 8 GB | 12,9 |

| vicosys® 6300 | Intel® Core™ i3-9300TE | 2,2 GHz | Bis zu 3,2 GHz | 4 | 4 | 8 GB | 16,1 |

| vicosys® 19001 | Intel® Core™ i7-10700E | 2,9 GHz | Bis zu 4,5 GHz | 8 | 16 | 16 GB | 35,4 |

| vicosys® 19001 mit i9-10900K | Intel® Core™ i9-10900K | 3,7 GHz | Bis zu 5,3 GHz | 10 | 20 | 32 GB | 85,5 |

Note: For this comparison, the number of integer operations was specified at the base clock of the CPU. The systems are delivered with turbo mode activated, which can be automatically throttled down to the base clock in unfavorable ambient temperatures.

Customs relevance:

Thermal imaging cameras are subject to special export regulations.

Different image characteristics:

Thermal images react differently to surfaces than classic visual cameras. Thin plastic films, for example, can appear transparent. Glass reflects the thermal radiation almost completely. The emissivity of the material is important. The higher this is, the less the objects reflect the surrounding heat radiation.

NUC (Non-Uniformity Correction):

The NUC operation is calibration procedure for image optimization and must be carried out regularly during the process via the Genicam command to ensure consistent image quality.

Contrast spread:

As the recorded temperature range of the thermal imaging camera is much larger than the range relevant for the evaluation, this must be set via the “Contrast spread” option in “Utilities for vicosys”.

Germanium lens:

Lenses of thermal imaging cameras for vicosys® are installed at the factory and are not interchangeable. This is a prerequisite for factory calibration and accurate temperature measurement.

Radiometric JPEGs:

Additional temperature data can be stored during fault image storage, allowing subsequent readout of the temperature measurement

Particularly suitable for passive thermography (e.g. hot components in the process), but also for active thermography with an external energy source. You can find more information on our

The use of deep learning with vicosys® requires three steps:

- Use the HALCON Deep Learning Toolkit for training processes to generate a model file

- Use HDevelop to apply the model in a Halcon script

- Copy the HDevelop script to the vicosys® with Deep Learning Runtime license and call the Halcon function via the Ruby calculation script command

Video Control Panel - dialog for setting up cameras with live images

IO test tool - For viewing the digital inputs and switching the outputs

Monitor window - Display of the current camera image (incl. zoom function)

Image report - Display of the gray values (0..255) of a small image section to view the edge shape or image brightness

HALCON scripts are called up directly in the test program. Parameters can be transferred via the webHMI and specific sub-programs can be executed. The user-friendly interface makes it easy to select, parameterize and visualize the processes.

For a better understanding of the functions and possibilities of the webHMI, we recommend our video tutorials in the download area:

The image processing is completely encapsulated and works without direct access by the operator (without Windows interface). Manipulation directly on the vicosys® system is not possible. This also enables real-time capability.

This means that the user interface can be limited to the intended parameters and functions. Encapsulation can be implemented via a web interface, for example, and is a basic requirement in many medical technology applications or safety-critical test processes. The scope of permitted operation can be defined on a project-specific basis.

| Process interfacees | EtherCAT, Profinet, Digital-I/O |

| Camera interface | GigE-Vision Onboard with POE in 1G, 5G, 10G |

| Machine interface \ service interface via vcwin: | |

| vicosys 6100: Ethernet 100/1000/2500 Mbit LAN | |

| vicosys 6300: Ethernet 100/1000 Mbit LAN | |

| vicosys 19001: Ethernet 100/1000 Mbit LAN | |

| Direct connection or camera interface without POE: | |

| vicosys 6100: 1000/2500 Mbit LAN | |

| vicosys 6300: 1000 Mbit LAN | |

| vicosys 19001: 1000 Mbit LAN | |

| Communication Interfaces | USB 3.0, USB 2.0 |

| more technical details | Manual in the Products section |

Easy networking of nodes with certified PROFINET (CLASS B)

The simple networking topology of PROFINET (ring and line) and many other fieldbuses guarantees a straightforward and reliable layout for plant and machine networks. The use of standard patch cables for PROFINET simplifies the installation.

Simple integration of the systems in SIEMENS SPS S7

The image processing system is integrated as a PROFINET IO device in the controller. Via the network, the controller can trigger image acquisitions of the systems, switch inspection tasks, and read/write process data. The standardized description files in GSD format support simple integration of the image processing systems in the plant control.

Robust and proven

PROFINET is an inexpensive and robust form of fieldbus technology that has successfully proved itself over a long period of time. It is supported by our vision systems.

We offer gateways for connecting vicosys® to all common fieldbus systems.

- For real-time Ethernet (EtherCAT, Ethernet/IP, PowerLink, etc.), we recommend the netTAP151 from Hilscher.

- For Profibus to Ethernet, we recommend the netTAP50.

- Both gateways allow the transmission of measurement data and control parameters.

Service

Vision & Control stands for personal support and customized solutions. Our range of services includes comprehensive services that go far beyond the mere provision of products:

Concept development

Technical advice on the optimum implementation of your requirements

Project support

Personal support throughout the entire project - from planning to implementation of your individual image processing solution

Software development

Support with the adoption of customer-specific software libraries and scripts

HMI development & individual adaptations

Customized user interfaces and software solutions

Efficient support on site or via remote maintenance

Flexible and reliable

Training courses

practical in-house training or set-up training directly at your premises