Object sided telecentric lenses

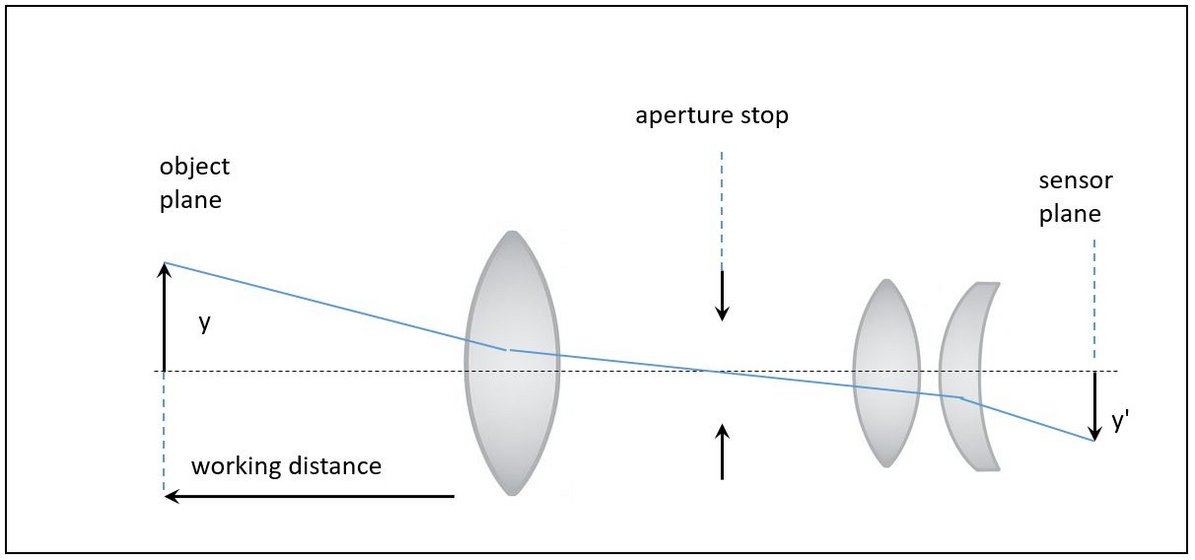

Object-side telecentric lenses allow the highest measuring accuracy.

The object-side optical beam path is parallel and objects are imaged at the same size within the depth of field.

Vision & Control has a range of different optics that can be the starting point for adjustments if the standard version does not 100% fit to the application.

Lenses for apllication with tuneable liquid lenses

Telecentric lens systems with integrated tuneable liquid lenses allow fast changes of the focus /working distance without moving components.

This is of high value, if the system requires a very low depth of field or if the object has very deep details.

Entocentric lens systems can also profit from the integration of tuneable liquid lenses for focus adjustment.

A further field of application for integration of tuneable liquid lenses in optical systems is the simulation of human ametropia.

Microscop lenses

Magnifying lenses are used for the inspection and measurement of very fine objects or details of objects in transmitting and reflecting light. The value of the magnification always refers to the size ratio of the object to the sensor or pixel size. Especially for reflected light applications, the option for coaxial integratron of lighting into the optical beam of the lens is available.

We are happy to provide individual solutions, such as high numerical apertures and longer working distances.

Wide angle (Fish eye) lenses

Wide-angle lenses are used for applications that require a large field of view.

Fish-eye lenses are a special type of wide-angle lens. They can be designed for image angles of more than 180° thanks to the specific alignment of optical elements. By designing retrofocal optics, a definite distortion or scaling of the image is achieved. Lenses with equidistant projection are particularly suitable for precise inspections even at a 190° image angle. This technology is used, e.g. for the inspection of bores or cavities.

Entocentric lenses

Entocentric lenses are typically high volume commodity products. But there are a number of special requirements that off-the-shelf entocentric lenses cannot meet, and we provide customer value through our OEM service.

- Ento-centric lenses with large magnification - 1 and above for high-resolution images.

- Ento-centric lenses with special focal lengths, both extra small and extra large focal lengths.

- Entocentric lenses for specific wavelengths (e.g. 450 nm or 1600 - 1800 nm) or specific spectral ranges (SWIR, MWIR, UV).

Lenses for large sensors or line-scan sensors

The application of large-format sensors and large line scan as well as TDI sensors leads to special requirements for the optical design and engineering of both telecentric and entocentric lenses. Full-format sensors with image diagonals between 43.3 mm and nearly 70 mm are steadily finding their entry into industrial applications,

likewise line scan and TDI sensors up to a width of 82 mm.

To meet these requirements, we provide our technology and know-how to contribute to the realization of innovative ideas for optical applications.

Scheimpflug lenses

Scheimpflug lenses are developed and applied for the imaging of angled, non-planar objects on an equally angled sensor plane. This specific shape of the optical axis allows best imaging quality and precise measurements in spite of the unusual orientation of object and optics. The Scheimpflug adapter ensures connection to a standard camera on the image side.

Optics for laser applications

LASER stands for “light amplification by stiumulated emission of radiation”.

special optical systems such as F-theta lenses, beam expanders and beam condensers are used for the guidance and control of LASER beams. Developing and manufacturing the most suitable optical system for the customer's specific application is what drives us and is our passion.

Multi-aperture lenses

Multi-aperture lenses are designed to be used for special applications where multiple wavelengths are directed from one lens to different camera systems. Consequently, multiple image processing applications can be performed at one inspection stage. The beam splitting of the different wavelengths is achieved by specific optical elements such as dichroic mirrors.

That helps saving space and time in fully automated production environments.

Splitfield lenses

Splitfield lenses are developed for special applications where the optical beam of several points of inspection (POI) is imaged on one sensor by a confocal deflection system.

This special type of customized lenses also offer efficiency in terms of space and image processing speed in the context of fully automated production.

OEM with Vision & Control? That makes the difference:

- We will extend our catalog portfolio. Thats the starting basis for customization.

- We provide the bestTime2Market for customizing or development.

- The MOQ for customizing or new development is significantly lower than with many competitors.

- Fast delivery of products based on our proven Assemble to Order principle.

Leading image processors rely on our experience in optical system design

Our comprehensive portfolio of optical systems reflects our broad range of technological experience. If our standard products do not meet all your requirements, we will use this expertise to your advantage and will be pleased to work with you on customized optical systems.

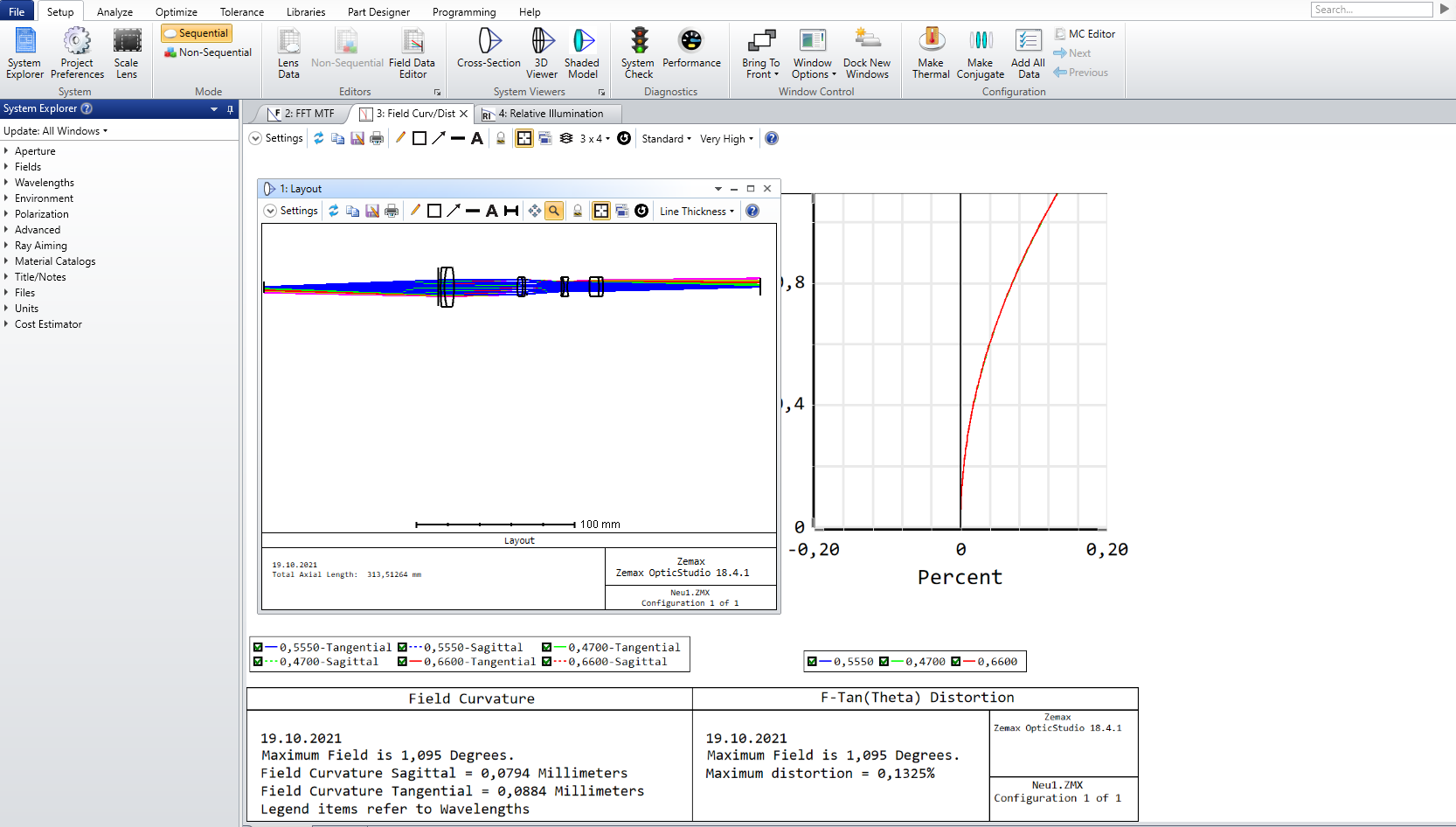

Our well-established team of optical designers and engineers works with the latest design software (ZEMAX and Inventor).

Through cooperation with reliable regional suppliers and well-established supply chains, prototypes are available on time and spare parts are available in the long term.

From small quantities to large series

In-house production (iso-certified)

Reliable delivery times

Sales staff record the technical and commercial conditions and make an appointment for an initial discussion with a developer.

In the first meeting, which is free of charge for you, all the necessary data and boundary conditions are specified and you then receive an offer.

After the order has been placed, we work together to draw up binding specifications.

After the prototype has been approved, the production data is worked out and handed over to the production department,

In accordance with the agreed delivery conditions, you will receive your optical system on time with a test report.