When it comes to inspection and evaluation of spatially extended objects, standard (endocentric) lenses and also conventional telecentric lenses quickly reach their limits. Problems of this kind can be solved by using telecentric large-field lenses with Fresnel technology.

The advantage of telecentric lenses, i.e. perspective-free imaging, has so far been contrasted by the disadvantage that they are severely constrained in their use by limited field of view sizes and also expensive. Due to the principle of using the parallel main beam path for imaging, the front lens must be larger than the object to be inspected.

As a result of this, the larger the component size, the greater the manufacturing work required to produce the optical components of telecentric lenses made of glass, which is reflected in their price. Moreover, lenses of this type are heavy, long and sensitive to mechanical damage.

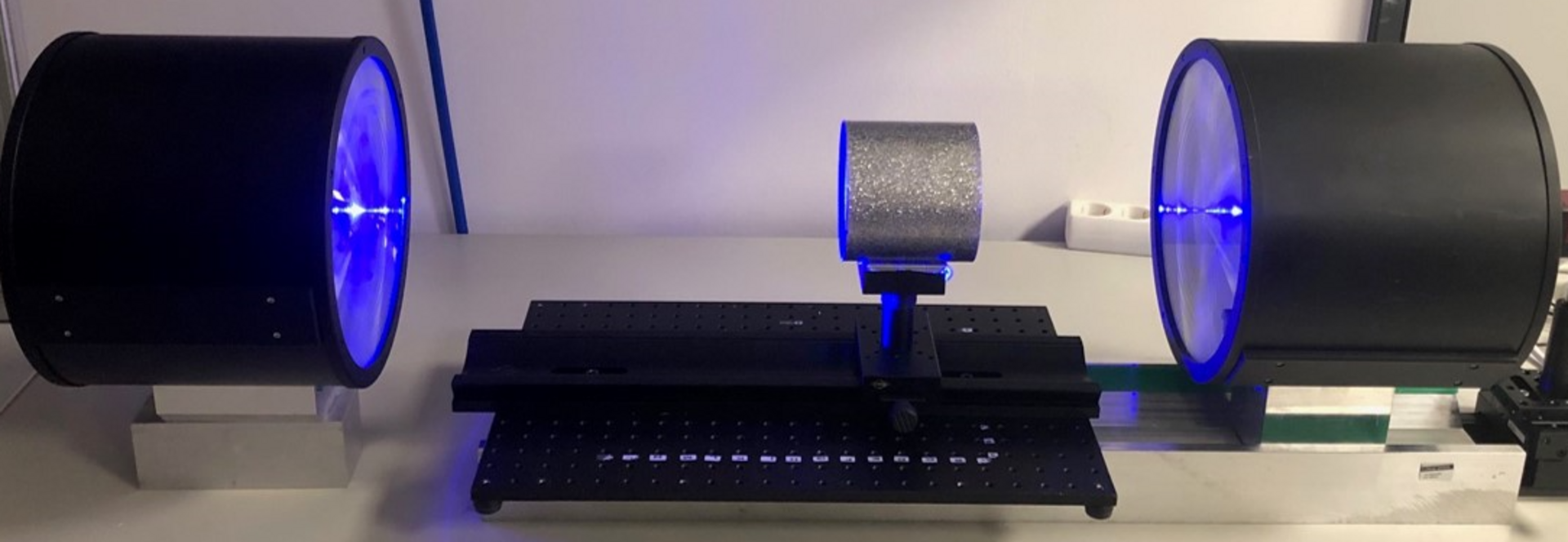

This is exactly where the considerations for telecentric large field lenses come in. By replacing the glass front lens with a very finely structured plastic stepped lens (10 zones / mm), considerably larger fields of view can be achieved with telecentric lenses. The use of Fresnel lenses improves the diameter-to-mass ratio and the diameter-to-length ratio enormously. In this way, telecentric lenses with diameters of up to 600 mm are possible.

The pixel resolution of the image sensor decreases as the field of view increases. As a result, the resolution that the lens can generate with its transmission of contrast (MTF) is no longer perceived by the image sensor. Even a high-resolution camera can only resolve 0.13 mm / pixel, i.e. just under 4 line pairs / mm, with a field of view of 170 x 130 mm, which makes the use of Fresnel lenses appropriate.

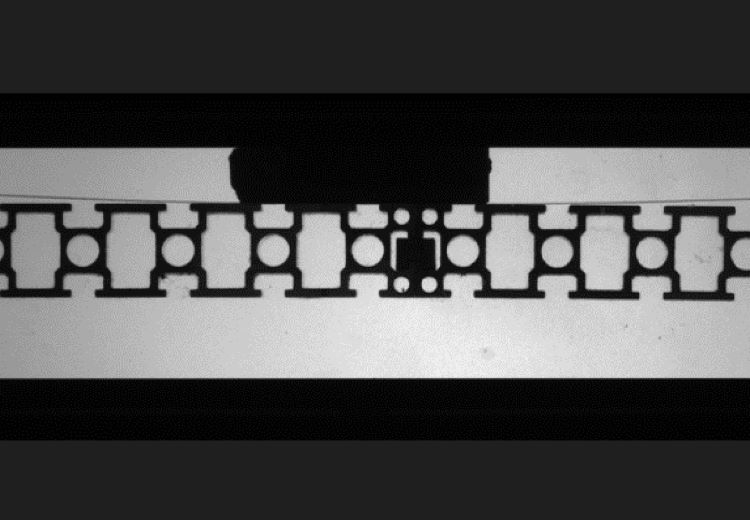

Since a single lens is used to determine the telecentricity, the distortion is less than 3%. Due to the low pixel resolution of the image sensor (and thus also measuring accuracy), large field lenses of this type are primarily used for presence checks and attributive feature tests and only to a limited degree for measuring applications. For the first time, applications that could previously only be solved with multiple cameras or the use of a handling system are now feasible with little effort.

Despite their size, the vicotar® telecentric wide field lenses are designed for industrial use. Robust mounting brackets ensure low-vibration installation. The dust-protected design, adjustable and fixable aperture and scratch-resistant front screen make them suitable for applications even under unfavorable conditions. The standard lenses have a C-mount camera interface. In OEM service, we realize fields of view up to 600 mm as well as camera connections for larger sensor formats, such as M42 and M72.

The wide field lenses using Fresnel technology can only be applied for monochromatic imaging in the VIS and NIR spectral range due to the existing and uncorrected lateral chromatic aberration.

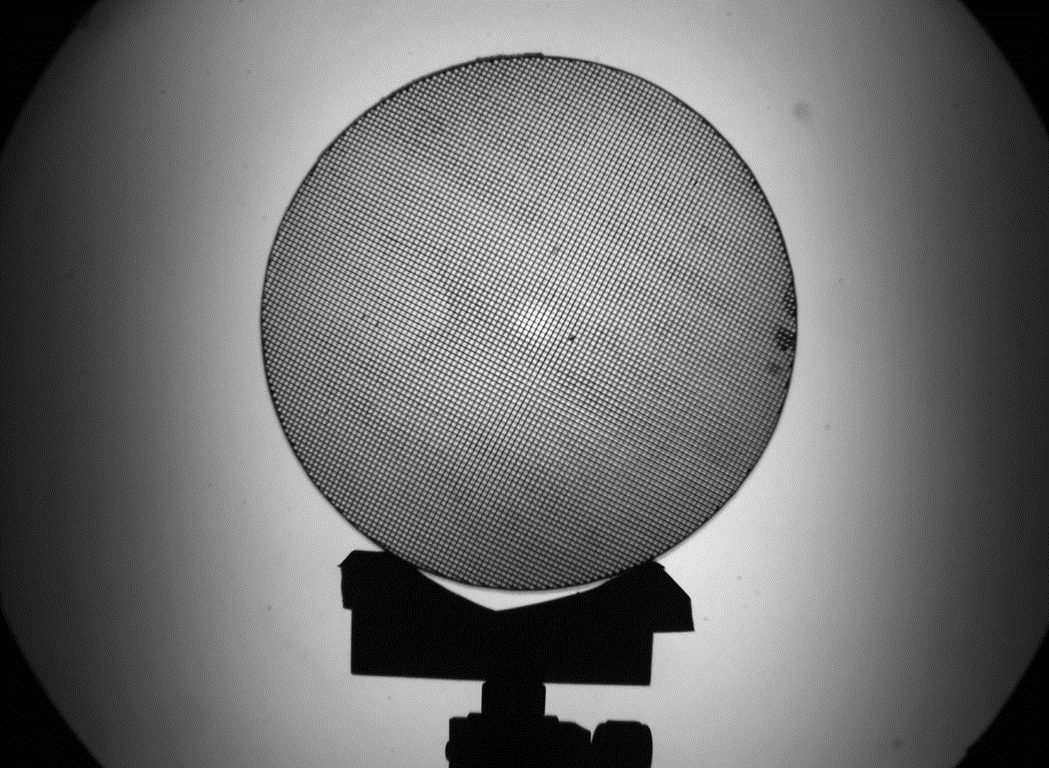

The applications for telecentric wide-field lenses are the inspection of large parts with wide spatial dimensions and holes, openings, notches, magazined parts as well as assembly and mounting inspection. Telecentric large field lenses prove their strength in these applications, as they are the unique solution for these inspection tasks.

The applications for telecentric wide-field lenses are the inspection of large parts with wide spatial dimensions and holes, openings, notches, magazined parts as well as assembly and mounting inspection. Telecentric large field lenses prove their strength in these applications, as they are the unique solution for these inspection tasks.