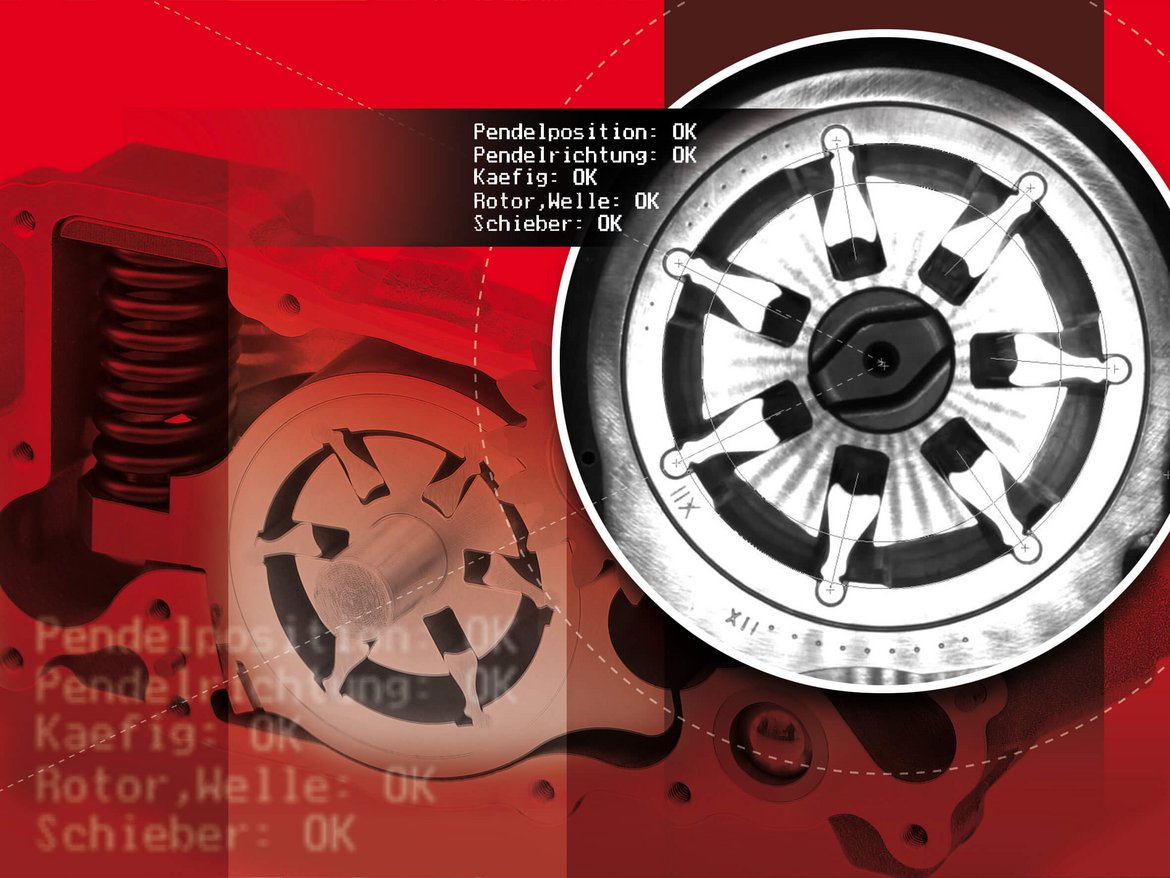

We all make mistakes sometimes. So when it comes to the manual assembly of truck oil pumps, which involves many steps, a full final inspection is absolutely essential. This is why the imaging specialists from Vision & Control have integrated an intelligent camera solution for final visual inspection in the test bench for pendulum-slider oil pumps at the company Mahle Filtertechnik. This system checks and documents all components to make sure they are present and correctly positioned.

At the heart of the test system is a compact camera from the pictor® M series. Along with a number of standard test sequences, image processing is already integrated on these models. With the Windows-based user interface of vcwin, pictor® M can be programmed and operated via Ethernet from any PC within the same network. Thanks to the graphical and intuitive user interface, this does not require in-depth IT skills.

The lens used is a fast entocentric lens from the VCN series. Together with a square diffuser plate with an aperture for the camera, an RK-series ring light mounted in front of the lens ensures shadow-free illumination of the test object.

Once the image has been captured, the first step is for the outer slider to be positioned using the function “Point probe”. From there, the test program finds the middle rotor and checks whether all pendulums are present. Any pendulums that are not latched are identified by searching for dark pixels along a circular path around the rotor. Based on the asymmetrical contour of the pendulums, the subsequent shape check identifies whether or not they are correctly oriented.

In the event of a problem, an incorrectly assembled oil pump is handed to the worker for reworking. Only if everything is in good order is the image saved with the documentation and the oil pump released with a test number printed using a dot matrix printer.